Lead is one of the most valuable metals known to mankind. Due to its physical and chemical properties, such as flexibility and resistance to corrosion, it has been used in ancient civilizations. The history of lead smelting and extraction goes back at least 8000 years. Ancient Egyptians widely used this metal along with gold and copper.

01Our services

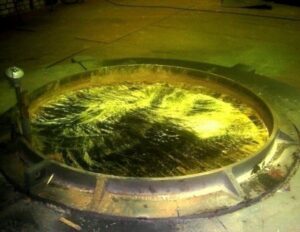

There are 2 lead refining or alloying boilers with a capacity of 25 tons in the factory, and each refining boiler works with a gas burner device. The refining capacity in the factory is 50 tons of lead per day. Each pot includes an outer shell, molten pot, refractory brick and torch.

Pig machine, in which molten lead is poured into molds at the beginning of the machine, and at the end of the machine, it is separated from the machine as a solid.

The capacity of the machine is about 10 tons per hour, the amount of production can be adjusted.

This machine can be manufactured and prepared with different capacities with the number of 90, 120, 140, 180 and 220 mol.

–Lead ingot weighing about 25 kg, which is bundled into 40 molds and weighing about 1000 kg for each bundle, is prepared to be sent to the customer.

These lead ingots are offered as refined lead ingots (soft lead) with a purity of 99.986% or as impure lead ingots (hard lead) with a purity of 99.3%.

The production capacity of the company is 50 tons of soft lead per day

Pure Lead Ingots ( 99.97%)

Elements Composition in %

Antimony (Sb) 0.001% (max)

Arsenic (As) 0.001% (max)

Tin (Sn) 0.001% (max)

Copper (Cu) 0.001% (max)

Bismuth (Bi) 0.030% (max)

Iron (Fe) 0.001% (max)

Nickel (Ni) 0.001% (max)

Silver (Ag) 0.005% (max)

Zinc (Zn) 0.001% (max)

Calcium (Ca) 0.0005% (max)

Sulphur (S) 0.0005% (max)

Aluminum (Al) 0.0005% (max)

Lead (Pb) 99.970% (max)

Designed

Build

Production of lead ingots

Why choose us?

– Filtration and dust collection system

Smelting furnaces and lead purification boilers in all lead recycling units from spent batteries are equipped with hoods to collect smoke and dust from the smelting operation.

These dusts are directed by communication channels from the hood to the gas cooler and from there to the filtration system, which are often dust filters.

The collected dust is re-directed through a separate process into the furnaces for remelting.